Unexpected shutdowns and planned halts leave behind different kinds of risk.

Some transformers sit cold for weeks, others hold residual heat in their cores or tanks. Either way, bringing one back online takes more than switching the breaker and watching the gauges. Especially when the unit sits in a mixed-use yard or under a shared protection scheme.

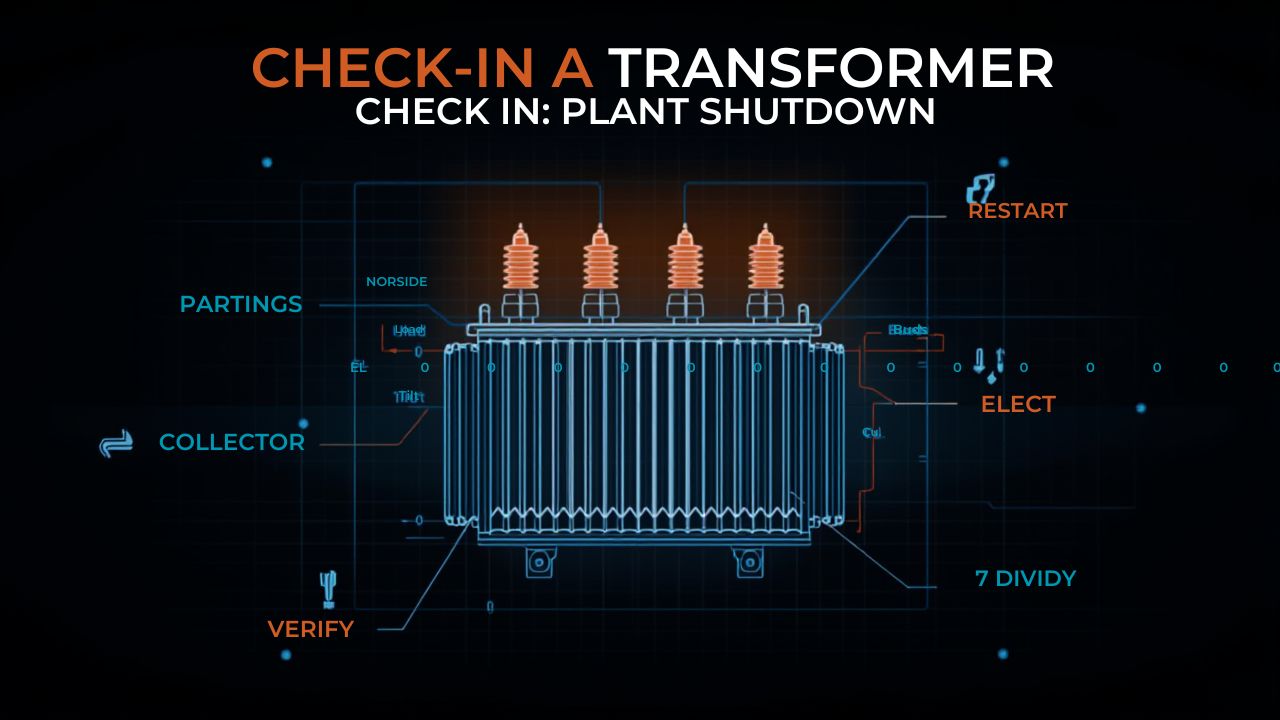

Here’s what often gets checked in our field jobs and why it matters more than it looks on paper.

Transformer oil holds clues about what the unit experienced during shutdown. It records temperature shifts, moisture ingress, and early-stage oxidation.

Even a short offline period can raise water content or degrade inhibitors, especially if the tank saw wide thermal swings.

Instead of relying on old test data, teams often inspect oil tint and gas bubble patterns before drawing samples.

Going beyond dielectric strength to check moisture and inhibitor levels offers a clearer view of how the unit aged while idle.

Seals tend to hold under load. When transformers cool down fully, the metal contracts, air shifts, and pressure points migrate. This often shifts how the conservator behaves or how silica gel breathers absorb humidity.

If the breather stayed saturated during shutdown, the silica inside may now be ineffective. That leaves the unit exposed to ambient moisture even before re-energization.

Teams also check if pressure relief devices locked in place after a slight vacuum event during cooling.

These are small details, but shape how stable the tank feels during the first hour of loading.

During shutdown, the temperature equalizes across the tank and core. That seems like a good thing.

But the issue is in how clamps and bracing behave once everything contracts unevenly. Bolted joints may loosen, CT cables may sag, and even bushing connections can develop micro-gaps at the contact surface.

These aren’t always visible from the top.

In many reactivation jobs, teams manually re-torque key lugs or run quick resistance tests across links that never triggered an alarm but carried marginal loads last time.

The goal is not just reconnection, but reconnection with integrity.

Protection doesn’t always stay updated with operations. During long halts, someone might’ve swapped relays, updated firmware, or merged feeders.

If the transformer’s trip logic still uses an earlier loading context, it may either under-respond or trip too early.

Engineers often review the relay curve and transformer rating side by side (just to confirm the math still works).

In some cases, a dry trip test adds value before energizing. Especially when new equipment was added downstream and now leans on the same trip group.

Restarting after a shutdown can trigger alarms even when the transformer remains healthy. Inrush current rises sharply at energization and can combine with existing harmonics upstream, pushing protection elements past their pickup thresholds.

This tends to show up in systems with switched capacitor banks or where multiple machines start together.

Checking energization sequences, staggered breaker timings, and inrush damping resistors (if present) helps avoid misread signals.

When loads come in fast, so should the clarity in how the system absorbs them.

Restarting a transformer is less about flipping it back on, more about understanding what changed during downtime, both inside the unit and around it.

That’s how we approach most support requests at our end.

Whether it’s an idle backup or a primary unit coming back after an overhaul, the focus stays on catching the subtle shifts before they become system-level issues.

Makpower's servicing team works closely with clients across reactivation, recommissioning, and post-trip diagnostics. That’s where most efficiency gains hide, in the details, before failure gets a head start. To know more, get in touch with us today.