Transformer oil doesn’t just cool. It insulates. It preserves internal paper. It signals problems.

So when oil leaks (even slowly), it changes how the unit performs and how much risk it carries. The issue is that most leaks don’t announce themselves.

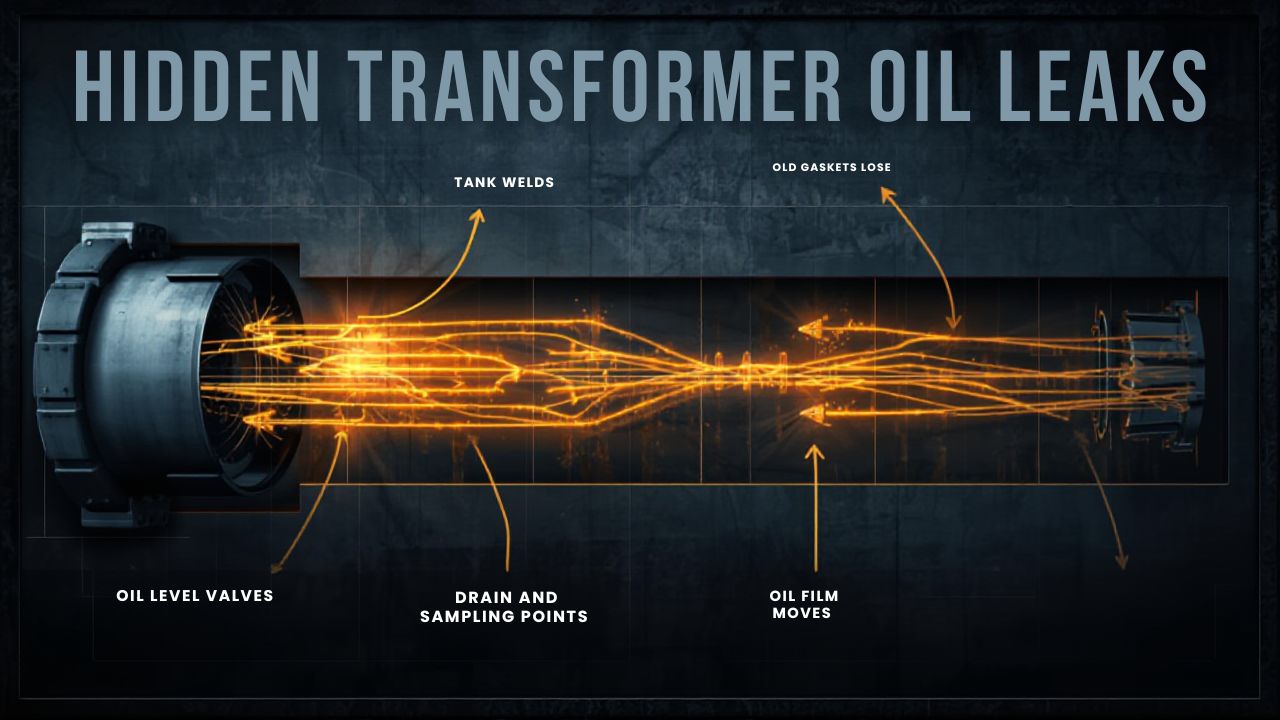

Here’s where they tend to begin and why they often stay hidden until something else fails.

Gaskets fail more from age than from pressure. Their outer edge might look fine, but deeper layers crack, harden, or shrink over time. That change often starts after a long idle period or temperature cycling across seasons.

Leaks form along the perimeter, then slowly creep in and out of contact with the sealing face. Teams spot them as dried rings of oil dust, not active drips.

The challenge is that tension at bolt points may feel tight even when the seal has lost shape internally.

Some leaks begin where the tank itself flexes.

Welds that once held strong may micro-fracture due to stress, thermal cycling, or vibrations near a support joint. They rarely split wide open, but they leak.

You might see brownish stains below the seam or feel a slight film even when pressure stays within spec.

Field teams often check weld edges near base plates and stiffener junctions. The signs are subtle, but once the outer paint flakes, those joints need closer attention.

Oil level indicators help, but only if they function properly. Many units show a healthy level even when oil has escaped slowly through the gauge assembly itself.

The glass may fog, seals may harden, or the float may jam near the top. That mismatch between perceived and actual oil content has caused insulation failure in some field cases we’ve seen.

Teams often compare gauge readings with volume checks to flag hidden losses early.

Valves at the bottom of the tank often become weak points. Their handles jam or seals dry out after too many cycles of exposure.

Small leaks start around the thread joint, especially if the valve was recently cracked open for oil sampling.

If you see an oily patch just below a cap or drain nut, it helps to check whether it resets or continues to build.

Some leaks only show under vacuum conditions or after shutdown, not while running.

One reason leaks stay unnoticed is that the oil doesn’t always drip. It travels.

It forms a thin film that spreads across paint, dirt, and flange faces. That film collects dust, then gets mistaken for normal surface aging.

In some cases, capillary action pulls oil away from the actual leak point, masking its origin.

Under the surface, that movement points to pressure shifts, thermal expansion, or seals breaking down higher up the assembly.

Our servicing teams often trace insulation wear or overheating issues back to unnoticed oil loss. That’s why reconditioning or field repair assessments always include close visual and physical checks at gasket edges, valve points, and seam lines.

You can miss leaks without missing oil. That distinction is important when planning refurbishments or switching a unit into heavier-duty operation.

If you're exploring oil reclamation, gasket upgrades, or condition-based diagnostics, reach out and we’ll walk you through what to inspect.