Some transformers always hum. That’s normal. But when the sound shifts (gets sharper, louder, or picks up a pulse), you know something inside has changed.

It may still run, no trips or alarms. But that sound could be the first sign that the core is vibrating differently, or the windings are under stress. Listening closely can give you more information than the gauges do.

Most of the time, transformer noise comes from magnetostriction. That natural vibration in the core steel happens with every cycle. But if that hum gets deeper or develops a slight beat, something inside might have shifted.

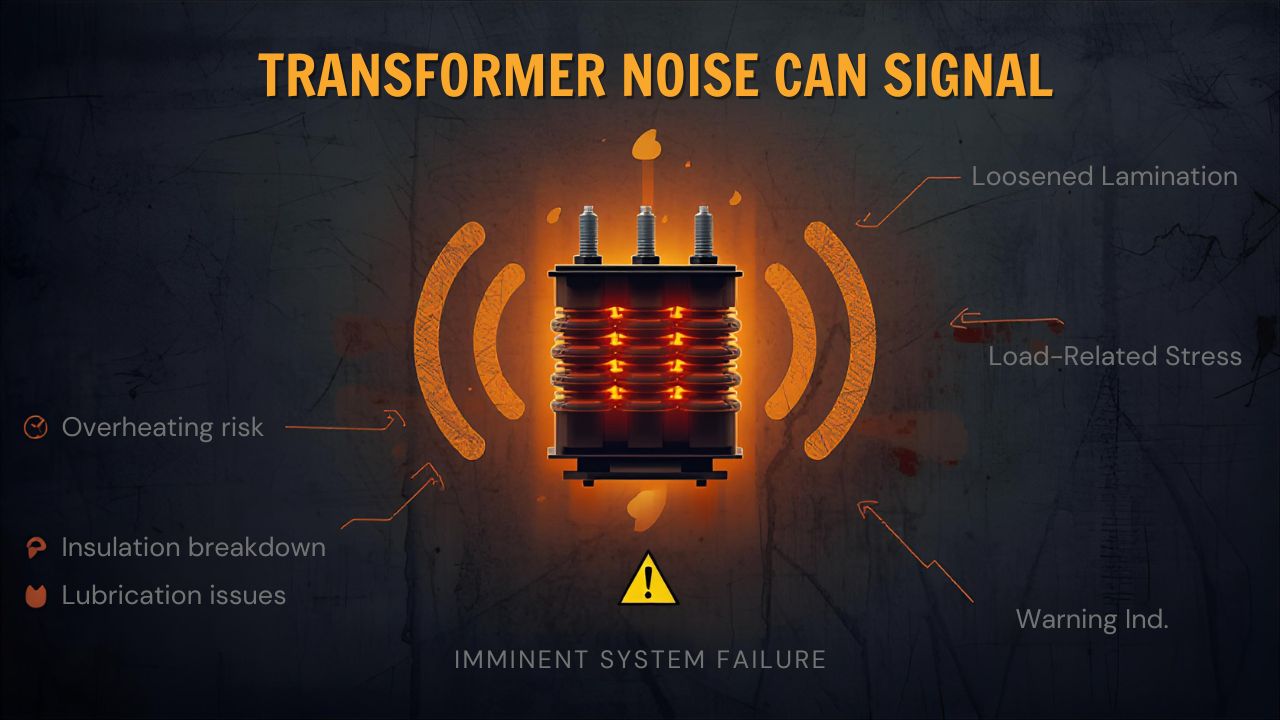

Core laminations, over time, may relax. The bolts holding them together can lose tension from thermal cycling. When that happens, the steel vibrates more freely. You might not see performance drops immediately, but you’ve lost mechanical stability that affects long-term efficiency.

Higher loads change how the coil behaves under current. A tight, steady hum may become a fast buzz when the load fluctuates sharply.

If that buzz fades once the load reduces, it might be harmless. If it lingers, something is straining.

It’s often tied to movement in windings or leads. Current creates a mechanical force that pulls against bracing. And when insulation or binding starts to fatigue, even slightly, that movement becomes audible before it becomes visible.

On-load tap changers make noise during switching. That’s expected. But if the clicking turns into rattling, or you hear an uneven chattering during normal operation, the contacts may not be aligning as they should.

It’s also common to hear intermittent crackling if arcing starts inside the tap changer. That’s harder to spot unless you’re right next to the unit, but the sound often shows up days before signs of pitting or overheating appear during inspection.

Transformer noise isn’t always from inside the tank. Terminal connectors, bushing clamps, or even loosened enclosures can vibrate under load and make sounds that mimic internal faults.

Listen for:

These don’t always signal internal issues, but they’re worth catching before they affect insulation or vibration-sensitive parts.

Transformers don’t fail in silence. They usually speak up first (just not through alarms). Noise changes, even slight ones, can reflect how the unit is holding together under load, vibration, and time.

We’ve seen transformers pass every electrical test and still get pulled for service because the sound told the truth first.

During upgrades or diagnostics, we factor acoustic changes into how we assess condition. It helps us catch issues that aren’t yet visible in oil, temperature, or test results, but are already taking root inside.

Sound offers more than annoyance or compliance checks. It can act as a live readout of the unit’s mechanical health.

In our service and upgrade work, especially where long-running transformers are still in operation, we use sound as one of many early signals.

If your transformer sounds different than it did last year, it could be trying to say something—quietly, but clearly. Get in touch with us to learn more.

As one of the trusted transformers manufacturers, we ensures every unit is built and maintained for reliable, long-term performance.