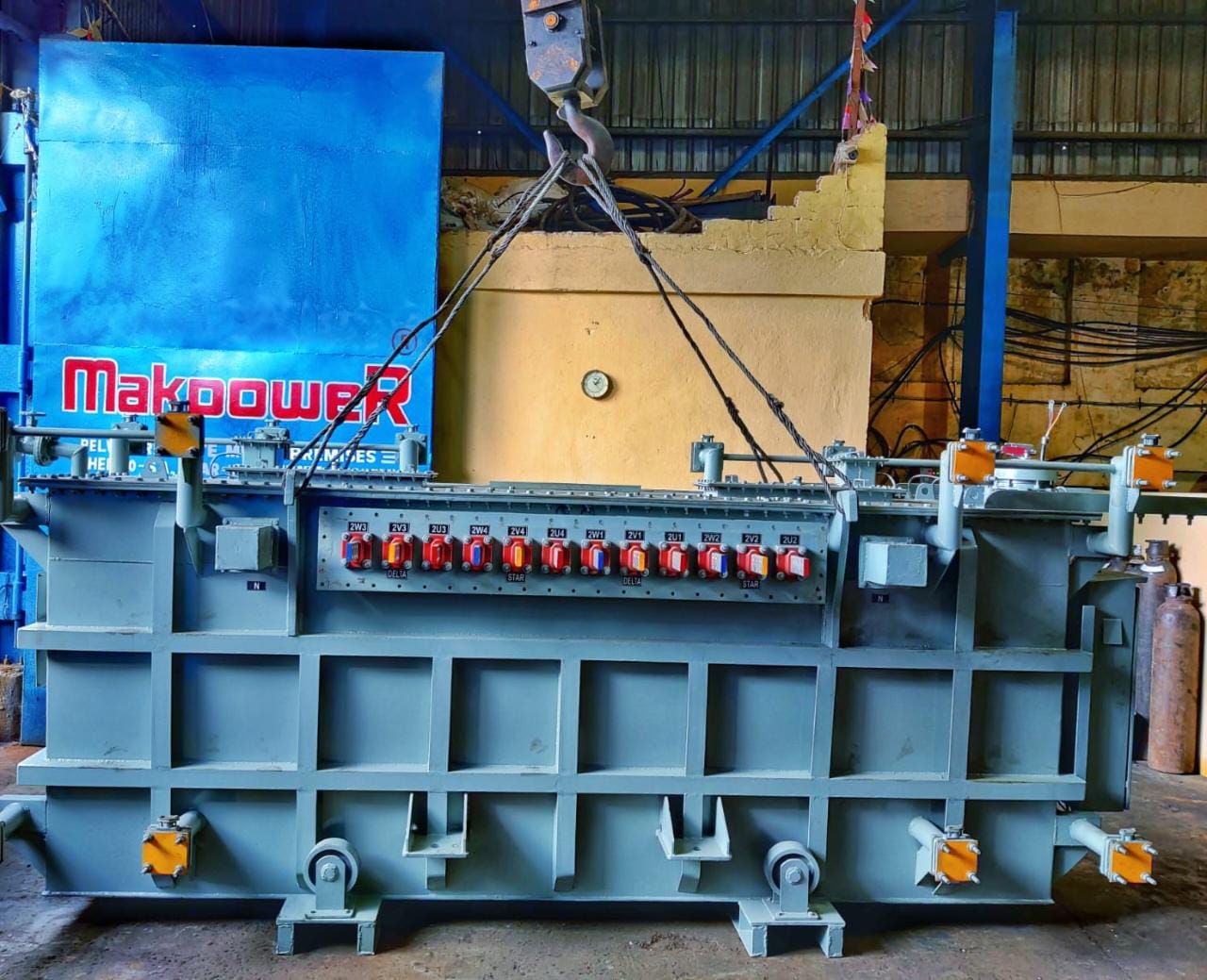

Range: 16 MVA, 33KV

Makpower designs and manufactures high-efficiency Induction Melting Furnace Transformers engineered for performance in modern foundries and metal industries. These transformers are integral to induction furnaces where the secondary voltage is precisely tuned and directly supplied to the furnace coil through a rectifier-inverter system. This setup converts standard frequency into medium frequency power for faster and more uniform melting.

Range: Makpower offers a versatile range of Induction Furnace Transformers up to 16 MVA and 33kV voltage class. Output voltages range from 400V to 1250V, tailored to specific furnace and rectifier requirements. These transformers support both 12-pulse and 24-pulse rectifier configurations, enabling enhanced power quality and reduced harmonic distortion for efficient furnace operation.

> Power Capacity: Up to 16 MVA.

> Voltage Class: Maximum input of 33kV.

> Output Voltage: 400V to 1250V, customizable as per furnace requirements.

> Frequency Compatibility: Optimized for medium frequency output via inverter units.

> Pulse Options: Supports both 12-pulse and 24-pulse operation modes.

> Cooling Type: Oil-immersed design with natural or forced cooling based on load demands.

Makpower offers multiple transformer arrangements to suit the electrical and space requirements of induction furnaces. These include single and multi-unit designs for both 12-pulse and 24-pulse configurations.

> Single Transformer with Dual LV Windings: One transformer with both star and delta windings.

> 12-Pulse System: Two transformers in a single tank, delivering phased outputs for reduced harmonics.

> 24-Pulse System: Four transformers integrated into one tank, engineered for high-load systems and improved power quality.

> Improved Efficiency: Designed to interface with rectifiers and inverters, enhancing melting speed.

> High Reliability: Proven performance in continuous-duty furnace applications.

> Flexible Design: Available in multiple configurations for 12 or 24-pulse operations.

> Compact Assembly: Multi-transformer units in a single tank minimize space and simplify installation.

> Low Harmonics: Optimized phase-shifting design for minimal power system distortion.

> Foundries: Used for efficient melting of ferrous and non-ferrous metals.

> Automotive Components: Supports induction heating processes for casting and forging.

> Aerospace & Defense: Enables precise melting in high-performance alloy manufacturing.

> Metal Recycling Units: Facilitates clean, controlled melting of scrap metals.

> Specialty Alloy Plants: Suitable for continuous duty and high-grade metal production.

Makpower ensures product reliability and safety through rigorous quality checks and adherence to IEC standards. Transformers are tested under actual furnace operating conditions to validate efficiency, voltage tolerance, thermal performance, and mechanical durability.

> Tested Designs: Proven under actual furnace loads with multiple successful field deployments.

> Regulatory Standards: Built in compliance with national and international electrical regulations.

> Built-to-Last: Engineered to withstand high thermal stress, voltage surges, and fluctuating currents.

> Custom Engineering: Makpower’s design team collaborates closely with clients to tailor solutions.

> After-Sales Service: Prompt support, maintenance, and component replacements ensure long-term efficiency.

> On-Site Commissioning: Installation support and performance validation at client location.

An Induction Furnace Transformer is a special type of transformer that supplies power to an induction furnace through a rectifier and inverter system. It delivers medium-frequency voltage to the furnace coil, facilitating the melting process.

The output voltage ranges from 400V to 1250V, based on the melting requirement and rectifier specifications of the induction furnace.

This design allows for better phase-shifting, compact footprint, and easier installation while enabling 12 or 24-pulse operations for clean power delivery to furnaces.